I recently ran across a blog (Sorry, don't remember whose) which discussed the quality of image and how pinholes drilled in soda can aluminum were inferior to those drilled in brass foil which were inferior to the pinholes you got with a premium pinhole camera like a Zero. So I thought I'd take a look.

The pinholes below were made with my standard technique for pinholes which are smaller than the diameter of the needle I'm using. I drill against a hard table top that the needle won't penetrate with some cardstock underneath it depending how far I want the needle tip to penetrate depending on the size pinhole I want. For pinholes approximately .15mm, I drill right against the table. For pinholes approximately .3mm, I use a matchbook cover, and for about .4mm a cereal box. The following examples are about .3mm. I then sand the burr that forms on the bottom side off with a piece of 400 grade emery paper. The pictures are all of the top side that the needle drilled into.

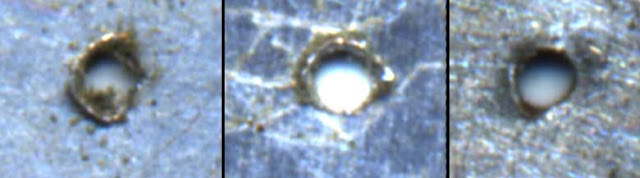

First the aluminum. When first drilled, it looks like the needle point splashed out a crown around the hole, and when sanded left all sorts of crap in the hole. Not a very good pinhole. Removing the debris was fairly easy by placing the needle back in being very careful not to enlarge the hole and giving it a spin. I wondered if I could get rid of this rough crown by sanding the side the needle entered. I knocked it down a little bit as in the middle picture and then really worked it over and did succeeded in minimizing it, but it looks like I distorted the edge a little bit.

I'm afraid my scanner freaks out when faced with extremely bright highlights on a shiny surface, so I had to switch to a cheapo microscope attachment on my phone so the image quality and scale is different, but the hole is actually about the same size

Then I wondered if it made much of a difference when completely drilling the pinhole through the material without the hard surface beneath it, so I drilled a couple with a piece of styrofoam under the material and pierced it completely with my number 10 needle to make a hole about .5mm.

I don't have a premium pinhole camera, but I thought it might be instructive to make a comparison to a Gilder electron microscope grid, which in addition is made in some even thinner brass.

This one happens to be a .15mm so it's also magnified a lot more

I guess technically it's a lot better.

At this point I should probably mount these on cameras and do an exhaustive comparison of image quality, but it's late.

Comparing 120 format images done with my 45mm Glenlivet Vertical Populist and 60mm Portrait Cameras, which have .3mm Gilder apertures, and the 45mm camera I made a few weeks ago, and the 60mm new Evil cube which have .3mm hand drilled pinholes in brass, I really can't see that significant a difference. I know I did the pictures for my experiments with developing paper in Caffenol with pinholes drilled in aluminum (although those negatives were 4x5), so you can still get some pretty decent pictures with that universally available material.

On f295, there would occasionally be an inquiry about how to make the sharpest pinhole images, and the discussion would inevitably devolve into statements that pinhole really isn't about sharpness so you probably shouldn't get too hung up about it.

No comments:

Post a Comment